PPC concentric ring, ported-plate, channel valve, damping plate design and poppet valves are replicated to meet or exceed OEM specifications. Valves and parts are available for all types of compression commonly used on our industry. PPC seats and guards are manufactured from Ductile Iron, Cast Iron, 1141 Carbon Steel, 4140 Alloy Steel, 416 Stainless Steel and other exotic materials upon request.

Poppet Valves commonly in the gas transmission industry. Using poppets instead of plates they offer the ability to maintain a high lift thus creating more gas flow through the valve.

In addition to the above valves, PPC can also redesign or re-engineer compressor valves when conditions favor such a change.

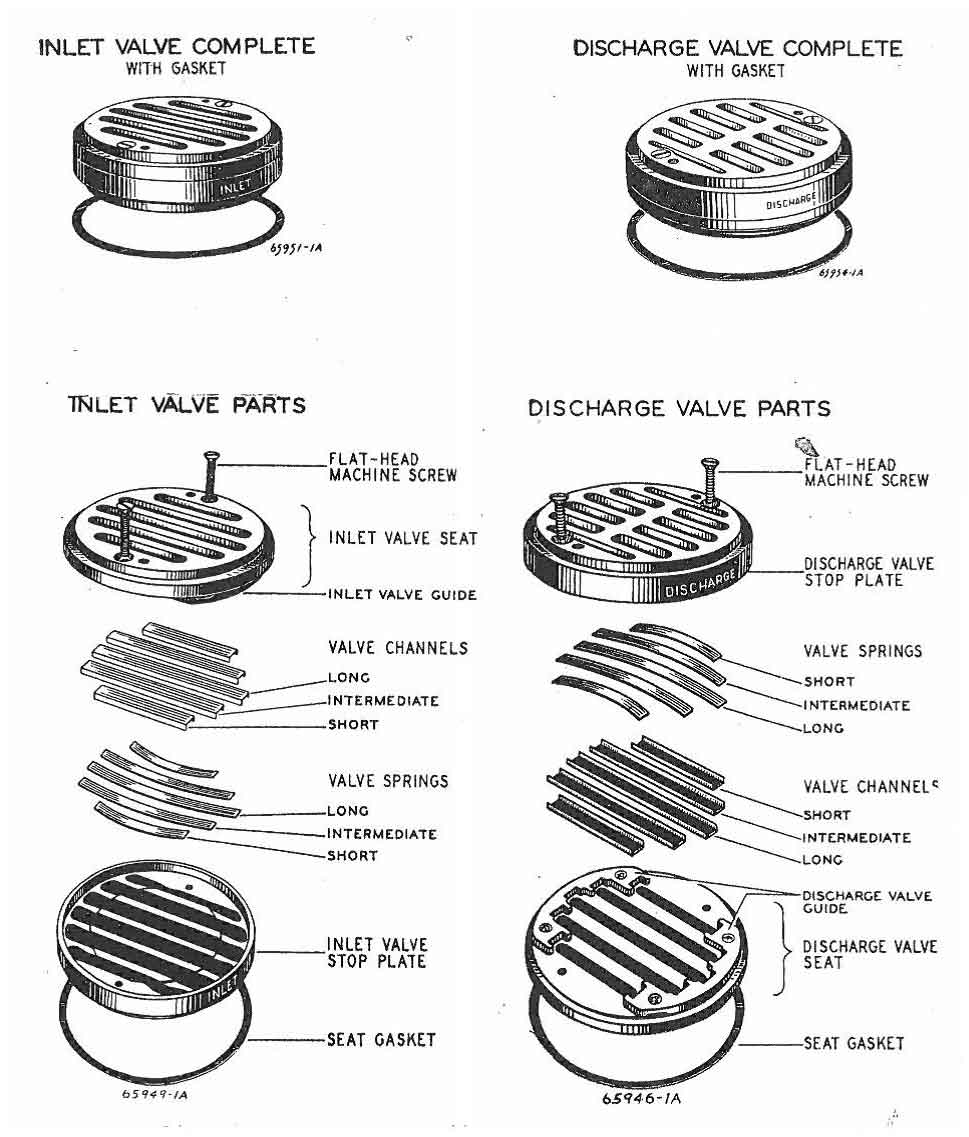

Channel Valves use channels and elongated springs to coordinate the flow through the valves. Channels sit on a seat plate and are guided by channel valve guides to stimulate the flow of the valve.